Why a VEROFLO Basket Strainer?

VEROFLO Basket Strainers are provided as a replacement for imported Wye Strainers and other Strainer designs. Our strainers have been designed for maximum performance with large capacities, low headloss characteristics, material of construction options and robust construction for pressures of up to PN64 and sizes up to DN1600. In addition, VEROFLO Basket Strainers are 100% locally manufactured, they have short lead times and are highly customisable to suit the client’s exact needs.

The performance of both Basket Strainers and Wye-Strainers (and other designs) and their success in a particular application, are governed by design parameters of the system. In order for the client to assess the best Strainer design for any particular application, the following points need to be considered:

Flow and Headloss

The first thing is to determine is the flow rate. Any flow rate over 35m3/h will most likely require a VEROFLO Basket Strainer in place of a Wye Strainer because of pressure drop considerations. This is because Strainers are usually sized so that their start up pressure drop is no greater than 15 kPa, with a line velocity not exceeding 2.4m/sec.

If you compare both strainer designs, size for size, VEROFLO Basket Strainers will exhibit less pressure loss than Wye and other Strainer designs. On average, a Wye or other Strainer designs, have a 50% higher headloss than VEROFLO Basket Strainer.

Capacity

Wye Strainer screens are smaller in dirt holding capacity than the baskets in VEROFLO Basket Strainers. Therefore, in a given application, a VEROFLO Basket Strainer will go longer between cleanings than a Wye Strainer will.

Maintenance and Cleaning

Not only do Wye Strainers (and other designs) have a smaller capacity in comparison to VEROFLO Basket Strainers, cleaning Wye Strainers is a complicated and messy affair. This is because the strainer leg of the Wye Strainer is situated below the pipeline, either pointing straight down or at an angle to trap debris. This means that when the bonnet of the Wye Strainer is removed to clean the screen, any fluid trapped in the strainer will drain immediately. Depending on the process media, and the location of the strainer, this can be a significant problem.

Further, some Control Valve or Water Meter manufacturers provide strainers housed in the body of the control valve or water meter. Not only are the capacities of these designs even more limited than those of Wye Strainers. All these designs provide difficulties in maintenance requirements similar to those of Wye Strainers. The difficulty of cleaning is compounded with the increase in size of these strainers.

Wye and other Strainer design sometimes have a blow-down connection on the bonnet to permit cleaning the screen without removing the bonnet. This method does not clean the strainer completely as debris may still remain in the strainer. Further this scouring during the blow-down procedure can lead to damage of the strainer.

VEROFLO Basket Strainers are easy to clean. The bonnet is on top. After making sure there is no line pressure, just remove the bonnet and lift out the basket to clean or replace it. If long term reliability and performance is important or, you in doubt, select a VEROFLO Basket Strainer every time.

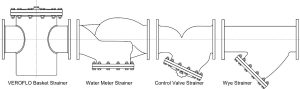

Fig. 1 – VEROFLO Basket Strainers are accessed from the top all other designs have their bonnets situated below the pipeline making removing the strainer a complex exercise specifically for larger diameter strainers. The Strainers are represented in scale to indicate the larger volume and therefore the lower headloss and maintenance requirements of the VEROFLO versus other strainer designs.

Cost

In comparing the cost of a VEROFLO Basket Strainer to that of a Wye or any other Strainer designs, you need to take into first take the following in to account:

- Headloss – the headloss of a VEROFLO Basket Strainer is 50% lower than that of a Wye Strainer or strainers designed that fit into Control Valve and Water Meter valve bodies.

- Capacity – A VEROFLO Basket Strainer has a flow through on average 3 times higher than that of the line diameter. In addition, the basket capacity is much larger than that of a Wye Strainer implying it will stay in service longer between cleanouts reducing the amount of maintenance.

- Cleaning of the Strainer – VEROFLO Basket Strainers, based just on their high capacity would need to be cleaned 300% less than Wye Strainers under equal circumstances. However, when it comes to cleaning, it will is easier to clean a VEROFLO Basket Strainer than a Wye strainer.

- 100% Local Manufacture – Every component in a VERFLO basket is 100% locally manufactured. All Wye Strainers and Control Valve or Water Meter Strainers are imported.

Taking the above into account, Wye Strainers are cheaper in smaller sizes and lower pressures but more expensive than VEROFLO Basket Strainers in sizes DN200 and larger.

Control Valve and Water Meter Strainers regardless of size, are 50% more expensive than VEROFLO Basket Strainers.

Conclusion

VEROFLO Basket Strainers provide a balance between cost, quality and performance that is unmatched in Wye, Control Valve and Water Meter strainers. This can be concluded from the following VEROFLO Strainer facts:

- 100% Locally manufactured – All other Strainer designs are imported

- Low pressure drop across the strainer – 50% or lower than Wye and Control Valve strainers.

- Low cost – Lower cost relative to the materials of construction as well as long term performance.

- Large Size and pressure range – available from DN50 to DN1600 and in pressure ratings PN10 to PN64.

- Protection of expensive pipeline components – cost effective protection insurance for expensive Pumps, Meters and Valves and other critical pipeline components.

- Reduced cleaning requirements – requires less cleaning than Wye Strainers. When required to be cleaned, is easier to do so than the cleaning to Wye Strainers.